Admix Admixer™ Static Mixer and Blender

Admix Admixer: Static Mixer and Blender

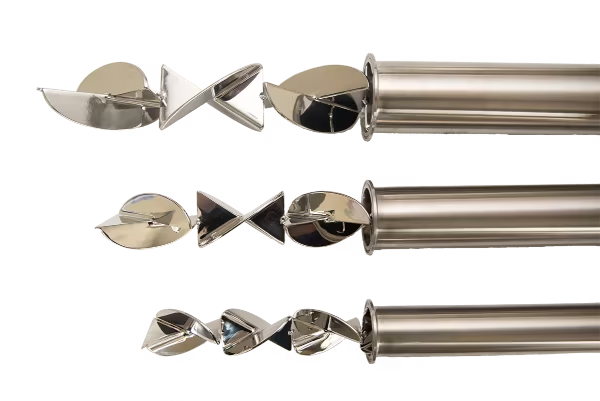

The Admix Admixer is a high-performance, all-stainless sanitary static mixer and blender, ideal for liquid dry processing and blending miscible fluids of various viscosities and densities. Additionally, it ensures even distribution of jelly in molten peanut butter and smooth integration of fruit into yogurt.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

Benefits of Admix Admixer

How the Admix Admixer Static Mixer & Blender Works

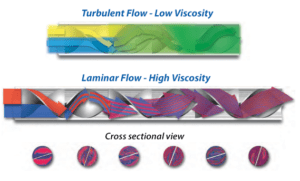

The Admix Admixer static mixer is designed for seamless processing of both laminar flow low viscosity and turbulent flow high viscosity fluids. Unlike conventional mixing kettles, the Admixer creates precise, homogeneous blends by utilizing radial momentum transfer, flow division, and inertia reversal. These principles eliminate stratification, temperature gradients, and material inconsistencies.

For complex immiscible fluid mixing, including gas-liquid blending and 2- or 3-phase emulsions, the Admix Admixer offers high shear control for predictable droplet size formation and stable emulsions. It also significantly improves heat transfer efficiency, making it an excellent alternative to plate and frame heat exchangers.

While many geometric shapes are used to create homogeneous flow, the degree of energy and mixing efficiency is not addressed. Thus, by using an elliptical or helical shape, smooth transitions are possible and no energy is wasted in back mixing. Triangular risers are in use to connect the angled elliptical shapes to prevent eddy dissipation at the element edges.

When in laminar flow, two or more fluids will remain adjacent to each other indefinitely unless disrupted. Therefore, the mixing elements divide the fluids and reorient by 180 degrees, by reversing from left hand to right-hand orientation, the rapid reversal at the interface enhances the mixing effect.

Industrial Applications

- Beverage processing: Efficient mixing of juice concentrates, flavors, and colorants

- Food manufacturing: Blending yogurt and fruit puree.

- Dairy processing: Mixing inclusions into ice cream.

- Chemical processing: Providing laminar flow for high viscosity solutions.

- Pharmaceuticals: Precise blending for liquid formulations

Related Process Equipment

The Admix Admixer works seamlessly with other process solutions, including:

- Boston Shear Mill – for high-shear dispersion

- DynaShear – inline high-shear mixing and emulsification

- Rotosolver & Rotostat – powerful high-shear mixing solutions

- Pentair Sudmo valves: Pentair Sudmo butterfly valve, Pentair Sudmo mixproof valve for hygienic fluid control

- Pentair Haffmans CO2 meter & Gehaltemeter for quality assurance

- Stainless steel pump cart – ideal for mobile processing

- Brewery pump cart – essential for beverage production

- Sterling Chiller & Sterling TCU (Temperature Control Unit) – precise thermal control

- TC 130 for temperature-sensitive processes

- Piab vacuum conveyor, Piab filters, and Piab parts for optimized powder handling