PET FOOD INDUSTRY

Understanding the Pet Food Industry

As people become more invested in their pets’ well-being, the demand for safe, quality pet food products increases. With the right equipment on hand, manufacturers like you can expand production capacity, improve product quality, maximize efficiency, and enhance safety.

Want to know how your business can capitalize on the growing pet food market? Let’s dive in.

Raw Materials Used in the Pet Food Processing Market

Pet food can consist of meat, meat byproducts, vegetables, and/or grains. Common meat byproducts include livers, kidneys, and lungs. Pet food can be dry or wet, raw or cooked, fresh or frozen, canned or bagged, carnivore or vegan.

Manufacturers in the pet food industry must meet quality standards and follow safety regulations to ensure products are nutritious and safe for consumption. While not as strict as the standards and regulations for human food, they still play an essential role in the pet food industry.

10 Pet Food Processing Applications

Pet food processing equipment is used for the following tasks:

Types of Pet Food

Dog Food

Dog food can be found in the form of dry kibble, pellets, treats, biscuits, or chews. It can also be wet or dry, with fresh and raw dog food becoming increasingly popular in today’s market. Safe dog food processing practices and manufacturing equipment are important because—just like human food—dog food is susceptible to bacteria like Salmonella, which can be especially harmful to older dogs with deteriorating health.

Cat Food

Cat food is also processed in dry and wet forms, although the latter is more common. Wet cat food typically comes in either cans, pouches, or tubes.

Dry Pet Food

Dry pet food, like kibble and treats, is made with freeze-dried meats and dehydrated fruits and vegetables that enhance the food’s flavor and nutritional value. These ingredients make for a healthy diet, which makes for a healthy dog.

Wet Pet Food

Wet pet food generally comes in cans, although pouches, foils, trays, and films are common as well. This type of pet food must be properly sealed to maximize its shelf life and maintain safety standards.

Raw Pet Food

The market for raw, or fresh, pet food continues to grow annually because it’s viewed as having more nutritional value and flavor. One thing to keep in mind is that raw pet food is perishable, so it must be stored properly due to a shorter shelf life.

Types of Pet Food Processing Equipment

Heat Exchangers

Heat exchangers—including shell and tube, plate and frame, and scrape surface models—maintain temperature control for pet food manufacturing processes. Temperature control is necessary to produce pet food that’s both nutritious and safe to consume. It also protects food from being overheated and overcooked, which can reduce its nutritional value. Heat exchangers also:

- Eliminate pathogens: Just like human food, pet food is pasteurized to remove harmful contaminants, including pathogens like Salmonella and E. coli, that can make animals sick. Pasteurization is especially important for raw and fresh pet food.

- Preserve nutrients: Heat exchangers help maintain the food’s nutritional value while it undergoes temperature changes.

- Enhance efficiency: Heat exchangers transfer heat between two fluids more efficiently than other equipment. This increased efficiency reduces energy costs along with the manufacturer’s environmental impact during production.

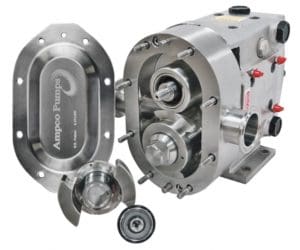

Pumps

Pumps move the raw, wet ingredients used to make pet food between process stages. They also maintain production efficiency by minimizing slowdowns and interruptions. Here are some common pumps used to process pet food and clean pet food manufacturing equipment.

- Twin screw pumps

- Positive displacement pumps

- Centrifugal pumps

Mixers

Industrial mixers play a key role in pet food production. They mix large quantities of ingredients—ranging from thick liquids to fine powders—quickly and evenly. As a result, this creates efficiencies such as increasing outputs, minimizing shutdowns, reducing costs, and enhancing product quality. It can also help manufacturers address challenges around wetting out powders into liquids, creating emulsions, dispersing solids, and even inducting powders into liquids.

How Pet Food Equipment Is Similar to Food & Beverage Equipment

The equipment used for pet food production is similar to that used for food & beverage production. Both types of equipment:

Why You Should Choose R-Cap Process Equipment

When you need custom equipment for your pet food manufacturing operation, look no further than R-Cap. For more than 30 years, we’ve provided the high-quality equipment you need in one convenient place. Plus, our machines can be customized for your intended applications, helping you achieve maximum production efficiency and reduce operation costs. If you have questions or concerns about a piece of equipment, our customer support team is available to help.

Don’t wait. Browse our collection today to find the industrial processing equipment you need to achieve the results you want.