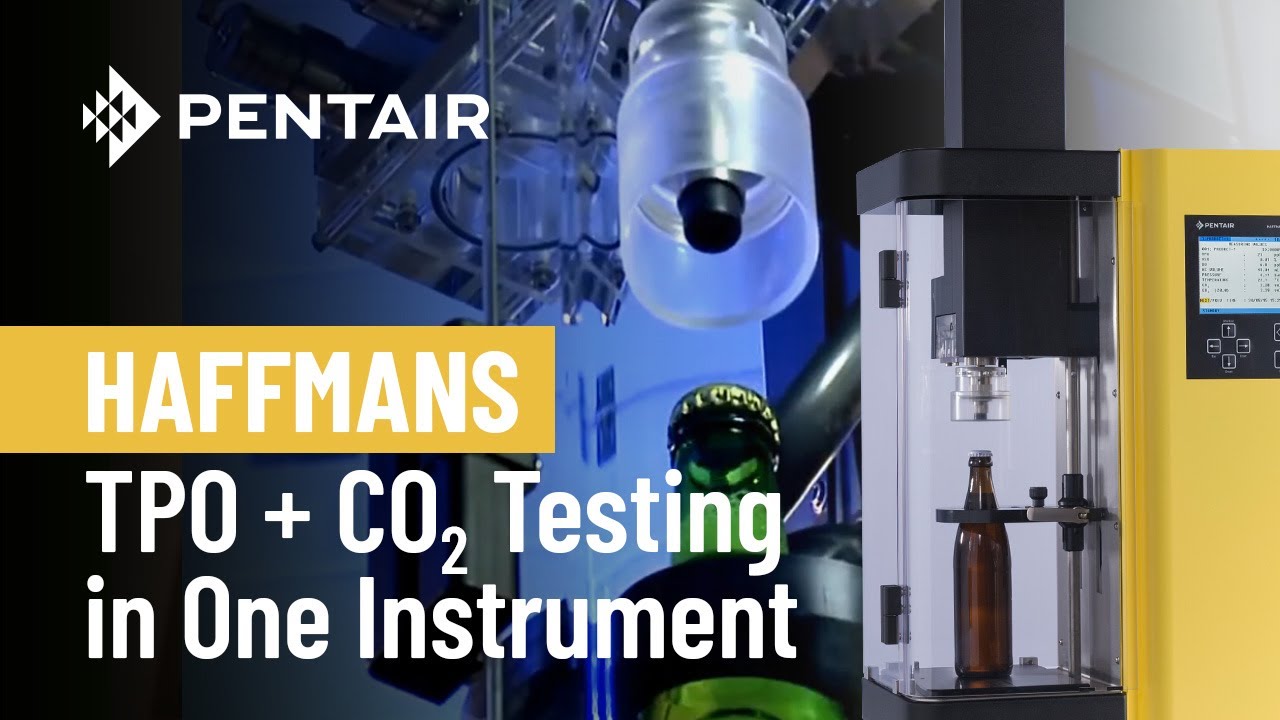

HAFFMANS – AUTOMATIC INPACK TPO/CO2 METER C-TPO

The differentiated measurement of headspace O2 and DO provides immediate insight into the performance of the filling operation. The multiple routine determinations of TPO and CO2 are fully automated. Up to 150 different product types/packages can be programmed and easily selected. The instrument is suited for the most common sizes of bottles and cans.

BENEFITS

The benefits of this product help you produce higher quality products so that you can maximize your ROI. Benefits include:

High quality beer and beverages in every package

All-in-one measurement: HSO, DO, TPO and CO2

FUNCTIONAL DESCRIPTION

In the beer and beverage industries both oxygen (O2) and carbon dioxide (CO2) are important gases. When it comes to product life and flavor stability, oxygen is detrimental. Preventing O2 pick-ups during the entire production and packaging process is of paramount importance. As a result, beer and beverages are produced with very low dissolved oxygen (DO) levels, to achieve consistent quality and high flavor stability during the products’ shelf life. The content of dissolved CO2 is decisive to the quality and taste of beer and carbonated beverages.

Beyond traditional TPO measurement methods and instruments, the c-TPO measures the headspace O2 and DO by the filler, while at the same time the liquid remains in the package and is not consumed by the instrument. Sample preparation time is skipped and lab space is minimized. The c-TPO also supports the well-known z-factor method according to Uhlig. The CO2 content is measured according to Henry’s Law.