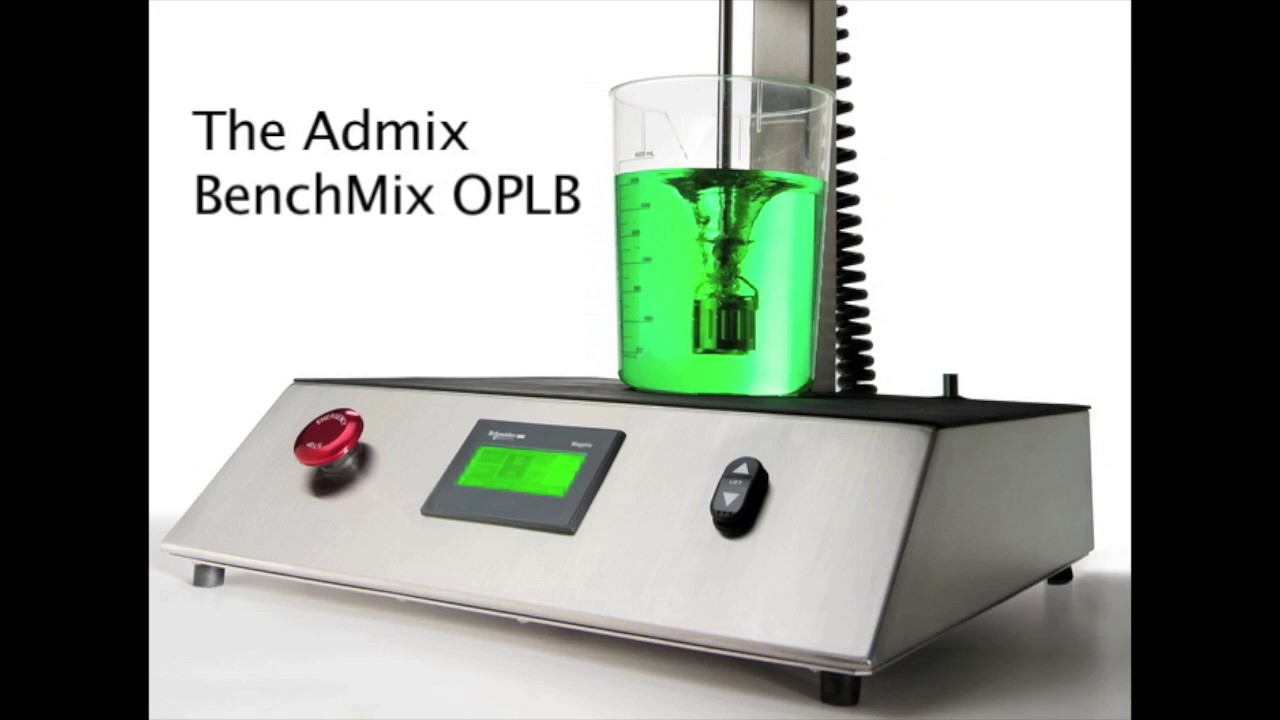

Admix BenchMix™ High Shear Lab Mixer

Unlock Seamless Product Development with Admix BenchMix High Shear Lab Mixers

Admix offers a comprehensive range of high-technology lab mixers, from compact 1-liter benchtop units to robust 20-gallon pilot plant floor models. Engineered for superior corrosion resistance, sanitation, and cleanability, all models are constructed entirely of stainless steel.

Why Choose Admix BenchMix?

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

HIGH SHEAR BENEFITS

HOW HIGH SHEAR LAB MIXER WORKS

The precision scale of the high shear lab mixer heads allows for complete validation, process qualifications, and Q/C analysis. As a result, this applies to pharmaceuticals, food components, and cosmetic formulations.

Therefore, the BenchMix Lab High Shear Mixer is designed with a simple operating touchscreen interface and provides shaft speeds up to 12,000 RPM and its 3 HP motor delivers unmatched power, performance, and scalability.

The pilot plant models (XP-02 and RS-02) operate at 3600 RPM providing the ideal tip speed for most applications. Also, speed controllers are available as an option to reduce the mixing intensity in thinner formulas.

Finally, the BenchMix high shear lab mixers provide a digital display of tip speed, mixing intensity, and pumping rates, allowing the operator to qualify and validate the process with as little as 1-10 liters (0.5-2.5 gallons) while providing the guidelines necessary to scale up to larger volumes.

This website shows just a small sample of the products we provide for a few industries. It’s our job to design the solution for you. We work with you to solve your processing equipment needs. If you don’t see some specific product on this website, just contact us by clicking the button below.