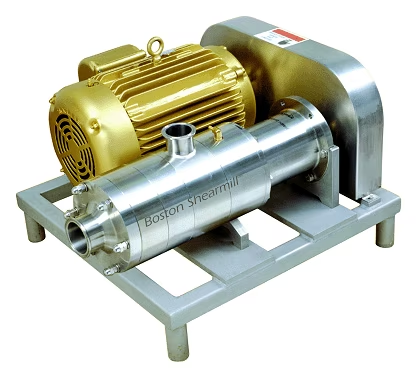

Admix Boston Shearmill™ Wet Mill/Homogenizer for Particle Size Reduction

Admix Boston Shearmill™: High-Intensity Wet Mill for Superior Particle Size Reduction

For industries demanding efficient and hygienic particle size reduction, the Admix Boston Shearmill™ (BSM) series of inline homogenizers and wet mills stands as a premier solution. Outperforming conventional shear pumps and colloid mills, the BSM achieves exceptional throughputs at extreme shear rates. Engineered to meet stringent hygienic standards, these wet mills are fully 3-A compliant, making them ideal for sanitary processing environments within the dairy, food, and beverage sectors, as well as pharmaceutical and chemical applications.

Achieving optimal particle size is critical in numerous processes. Whether you require milling of soft particles to sub-micron levels (<1 micron) or reducing hard particles to the 1-2 micron range, the Boston Shearmill delivers consistent, superior particle size reduction, often in a single pass, even at high production rates. This level of performance surpasses standard admix mixer technology and positions the BSM as a leader in admix high shear mixer solutions.

Leveraging advanced rotor-stator technology, these wet mills offer significant advantages in continuous, 24/7 operations. The BSM is expertly designed to mix, disperse, emulsify, pulverize, macerate, crush, and homogenize a wide range of substances. It excels at reducing solid particles with minimal dust formation and is robust enough to handle uneven flow patterns, pressure fluctuations, and jolts inherent in demanding industrial settings.

With hundreds of successful installations, Admix Boston Shearmills are trusted across diverse applications, including tomato paste standardization, salad dressing and mayonnaise processing, pet food production, flavor emulsions, pharmaceutical preparations, API blending, and polymer blends. When comparing admixing vs mixing with conventional methods, the Boston Shearmill provides a clear advantage in efficiency and particle size control.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

Admix Boston Shearmill Wet Mill/Homogenizer: Key Benefits

How the Boston Shearmill Achieves Superior Performance

The Boston Shearmill is engineered to process very high throughputs at extreme shear rates, consistently producing average mean droplet sizes from 0.05-3 microns. This exceptional performance is achieved through its innovative multi-slot rotor and multi-port stator construction.

Each shear head within the homogenizer features a double ring design, creating two stages of mixing at both the rotor and stator. This innovative design results in three distinct, high-intensity work zones at each rotor/stator location, as the mixture precisely passes between:

1. The first set of rotor slots (or teeth) and the first ring of slots on the stator.

2. The first ring of slots on the stator and the second ring of slots in the rotor.

3. The second ring of slots in both the rotor and stator.

Boston Shearmill models typically feature three shear heads in series, providing a total of 6 mixing stages and 9 high-intensity work zones to effectively handle even the most challenging processing demands. This multi-stage, high shear approach significantly outperforms simpler benchtop lab mixer designs and offers a robust industrial solution.

Boston Shearmill: Key Features at a Glance

How It Works: Detailed Rotor/Stator Design

Admix Boston Shearmills are constructed with a precision-engineered multi-slot rotor rotating at high speeds in close proximity to a multi-port stator. Each homogenizer shear head features a double ring rotor and stator design. This configuration creates three distinct, high-intensity work zones at each rotor/stator location:

Between the first set of rotor slots (or teeth) and the first ring of slots on the stator.

Between the first ring of slots on the stator and the second ring of slots in the rotor.

Between the second ring of slots in both the rotor and stator.

Models equipped with three shear heads deliver nine high shear work zones, providing unmatched processing power for the most challenging applications. These advanced wet mills are capable of processing very high throughputs at extreme shear rates, achieving an average mean droplet size of 1-3 microns.