Admix Boston Shearpump, Inline High Volume Mixer for Particle Size Reduction

Revolutionize Particle Size Reduction with the Admix Boston Shearpump – An Inline High Shear Mixer Solution

For professionals demanding superior particle size reduction and efficient admixing in continuous processes, the Admix Boston Shearpump (BSP) stands as the premier inline high shear mixer. Surpassing traditional shear pumps and colloid mills, the Boston Shearpump delivers unmatched throughput with moderate to high shear rates. This robust admix mixer is engineered for seamless admixing of solids and powders into viscous liquids, providing consistent and repeatable results crucial for demanding applications. The BSP is specifically designed for processes requiring product “texturizing” and adheres to the most stringent hygienic standards, including 3-A TPV compliance.

Built for continuous 24/7 operation, the Boston Shearpump excels in a multitude of processing tasks. From mixing and dispersing to emulsifying, pulverizing, macerating, crushing, and homogenizing, this versatile machine efficiently reduces solid particles at high volumes. Its robust design readily handles uneven flow patterns, jolts, and pressure fluctuations, ensuring consistent performance in challenging environments.

In industries like food, dairy, and beverage, where precise particle size reduction is paramount, the BSP offers significant advantages over conventional wet milling techniques. Utilizing advanced rotor-stator equipment, the Boston Shearpump achieves remarkable milling capabilities. In a single pass at high production rates, it can reduce soft particles to below 10 microns and hard particles to the 10-20 micron range. Furthermore, integrating the BSP upstream of a high-pressure homogenizer pre-conditions the product, enhancing overall product quality, boosting homogenizer capacity, and minimizing homogenizer maintenance expenses.

Admix’s extensive experience includes countless successful inline mixer installations across diverse applications. From tomato paste standardization and salad dressing production to mayonnaise processing, pet food manufacturing, flavor emulsions, pharmaceutical preparations, API blending, and polymer blends, the Boston Shearpump has consistently delivered superior results.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

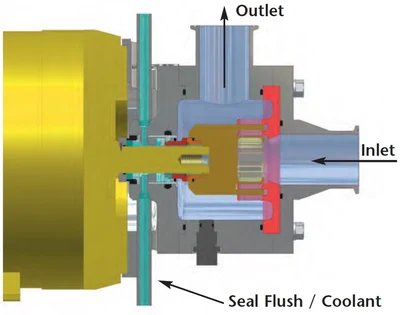

How the Boston Shearpump Achieves High Shear Mixing

The Boston Shearpump achieves exceptional shear rates and tight particle size distribution through its innovative design. At its core is a multi-slot rotor that rotates at high speed within a close-tolerance, multi-port stator. The shear head of this inline mixer features a double-ring configuration, creating two distinct stages of mixing action at both the rotor and stator. This ingenious design results in three high-intensity work zones at each rotor/stator interface:

1. First Work Zone: Between the initial set of rotor slots (or teeth) and the first ring of stator slots.

2. Second Work Zone: Between the first ring of stator slots and the second ring of rotor slots.

3. Third Work Zone: Between the second ring of slots in both the rotor and stator.

This unique configuration allows Boston Shearpump models to achieve two mixing stages with three work zones from a single shear head, simplifying operation while effectively addressing even the most demanding processing requirements.

Boston Shearpump: Key Features and Benefits

High-Intensity Inline Mixing

- Designed for continuous 24/7 operation, ensuring maximum uptime.

- Exceptional particle size reduction capabilities for consistent product quality.

- Versatile performance: Disperses, emulsifies, pulverizes, macerates, crushes, and homogenizes.

Uncompromising Hygiene

- 3-A Compliant: Meets 3-A sanitary standard #73-01 and USDA-AMS standards, guaranteeing hygienic operation.

- Constructed with all stainless steel mix head, shaft, drive, and motor options for demanding sanitary environments.

- CIP (Clean-In-Place) capable design with no crevices, deadlegs, or open threads for simplified and thorough cleaning.

Process Integration

The Boston Shearpump (BSP) excels at delivering high throughputs with exceptional shear rates, outperforming conventional shear pumps and colloid mills. It is ideally suited for inline mixing of solids or powders into viscous liquids, providing consistent and repeatable shear for critical processes. The BSP is the ideal solution for applications requiring product “texturizing” and where adherence to the highest hygienic standards, including 3-A TPV compliance, is mandatory.

Modular and Adaptable Design

- Wide range of models available, offering varying capacities, power consumption, and tip speeds to match specific process needs.

- Configurable with up to 3 shear heads and 3 shear levels, providing up to 9 shear zones in a single pass for ultimate customization.

Engineered for Ease of Use and Maintenance

- Simple operation with a single shear head design.

- Easy to clean CIP design minimizes downtime and maximizes efficiency.

- Low maintenance design reduces operational costs and ensures long-term reliability.

- Minimizes dust formation during solids reduction, contributing to a cleaner and safer work environment.