ADMIX DYNASHEAR SANITARY INLINE MIXER

WHAT IS THE ADMIX DYNASHEAR SANITARY INLINE MIXER?

Designed as a high speed, high shear mixer, and emulsifier for continuous processing, today the DynaShear sets the standard for inline mixers with hundreds of installations in place for dairy, beverage, salad dressing, and mayonnaise food processing, pet food, flavor emulsions, and pharmaceutical/API applications.

Constructed completely of 316 SS (internals, housing, shafting, and base), its unique dual-stage axial and radial heads provide optimal throughput and flow. In addition, the shear rates generated ensure droplet and particle size reduction down to 3-5 microns with excellent distribution.

Some processors use DynaShear for a single pass continuous mix after powder addition upstream, while others recirculate product back through a batch reactor for a 3-5 minute total blend time. Thus, this easy-to-install, cost-effective, low maintenance mixer is also a flagship product with some models available through our Quick Ship program. Contact us for more info.

If your application requires higher intensity, more milling, and greater particle size reduction, the versatile Boston Shearmill generates droplet and particle size reduction down to 1 micron while withstanding uneven flow & process fluctuations.

BENEFITS

HOW IT WORKS

The performance and success of high shear in-line mixers can be measured in droplet size (particle size) reduction, particle size distribution, and flow/processing rates under varying viscosity conditions. The DynaShear excels in all of these characteristics when compared to competitive high shear inline mixer.

A single pass through the DynaShear results in product quality typical of several passes through conventional mixers.

The DynaShear is the first inline emulsifier to feature a dual-stage tandem head design that combines the benefits of both an axial and a radial stage creating excellent shear and flows characteristics.

Primary Axial Stage

The axial stage consists of a high flow rotor feeding into a stator with multiple small ports, forcing material between their faces and out through the ports. Therefore, this mechanical and hydraulic action causes a tremendous shearing action and “pre-mixes” the material prior to the secondary stage.

Secondary Radial Stage

The radial stage consists of a radial, high flow rotor discharging through a slotted stator providing additional mechanical and hydraulic shear. The centrifugal force allows the mixture to be pushed away from the shaft and along the radius of the stator. Then with high-speed expulsion occurring at the edge of the slots. This stage provides a substantial momentum change inflow, resulting in beneficial residence time that further refines the mixture.

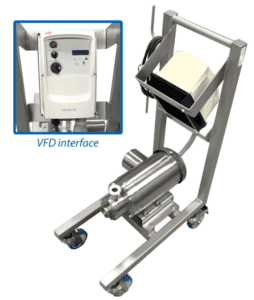

NEW! LAB SCALE DYNASHEAR

The DynaShear 215 is a lab scale disperser/emulsifier designed for product development, simulation and scale-up. This lab model is mounted to a mobile cart and includes a VFD for accurate scale up. You’ll achieve predictable, repeatable results from lab to full production!

DYNASHEAR QUICKSHIP PROGRAM

• EASY TO INSTALL!

• APPLIES TO SELECT CONFIGURATIONS OF THE DS-215, DS-425 AND DS-575 MODELS.