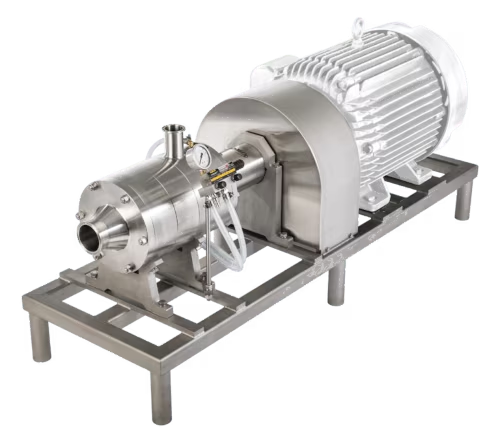

Admix MayoMill - Inline Wet Mill

Admix MayoMill Inline Wet Mill: Revolutionize Your Mayonnaise Production

For Seasonings, Sauces, and Condiments Professionals Seeking High Shear, High Speed, and High Flow Processing.

The US seasonings, sauces, and condiments market is a powerhouse, generating over $22 billion in revenue, with mayonnaise alone accounting for a staggering $2 billion annually. To thrive in this lucrative sector, you need advanced processing solutions. Introducing the Admix MayoMill Inline Wet Mill, a revolutionary high shear mixer engineered to overcome the limitations of conventional colloid mills. This innovative system delivers superior performance for manufacturers seeking to optimize their production of mayonnaise, dressings, and similar emulsions. Built upon proven Boston Shear Mill technology, the Admix mixer ensures consistent product quality, reduces downtime, and enhances operational efficiency. Consider this benchtop lab mixer scale technology, scaled for industrial throughput and reliability.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

BENEFITS

The Admix MayoMill is designed to mix, disperse, emulsify, pulverize, homogenize, and reduce solid particles with minimal dust formation. It does so by its many benefits, including:

Mayomill Inline Wet Mill: Engineered for Continuous Operation

The Admix MayoMill is engineered for continuous, 24/7 operation in demanding processing environments where downtime is costly and disruptive. While the fundamental performance metric of any inline mixer or colloid mill is its processing effectiveness, operational reliability and low maintenance costs are equally crucial.

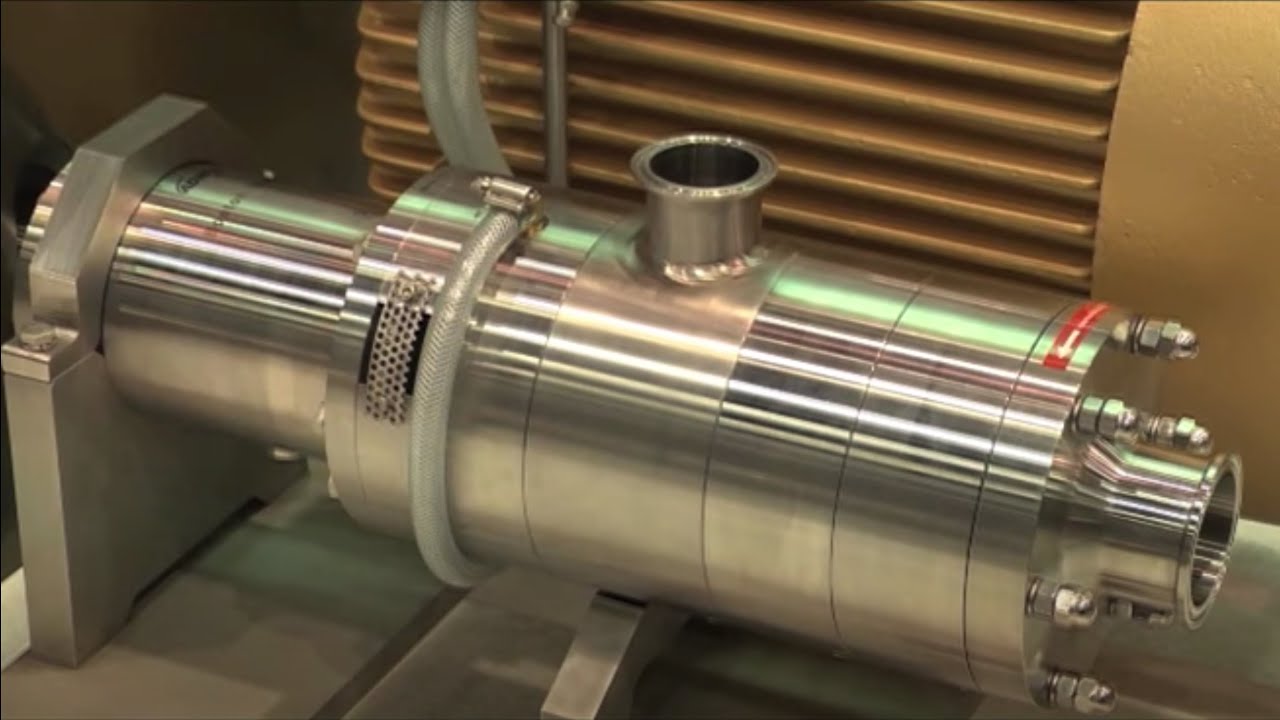

By integrating proven Boston Shearmill technology with cutting-edge innovations in rotor-stator designs, Admix engineers have developed a series of inline mills specifically optimized for balancing shear rate and flow. Simple in design yet robustly manufactured for exceptional durability, the Admix MayoMill significantly reduces the downtime typically experienced with conventional colloid mills, ensuring consistent, high-quality production with minimized interruptions.

Mayomill vs. Colloid Mills: Key Feature and Benefit Comparison

Harnessing the power of advanced rotor-stator technology, the Admix MayoMill unlocks a range of benefits specifically tailored to meet the demands of continuous wet milling operations. More than just machinery, our wet mills are reliable partners, designed for tireless 24/7 operation, performing a comprehensive range of functions: mixing, dispersing, emulsifying, pulverizing, macerating, crushing, homogenizing, and fine particle size reduction. All this is achieved with minimal dust generation, contributing to a cleaner and safer work environment. Furthermore, the MayoMill is built to withstand the rigors of fluctuating flow patterns, pressure variations, and sudden jolts, embodying the innovative, trustworthy, supportive, and helpful ethos our brand represents. We take a professional, informative, and thoughtful approach to ensure our machinery not only enhances efficiency but also drives excellence in every particle processed.

In the demanding world of food processing, continuous operation and minimal maintenance are paramount. While the performance of any inline mixer or colloid mill is judged by its processing efficacy, reliability and uptime are equally critical. The Admix MayoMill is engineered for 24/7 operation, ensuring uninterrupted production schedules when downtime is most costly and disruptive. Its simple yet robust design, drawing on Boston Shear Mill principles and advanced rotor-stator technology, drastically reduces the downtime typically associated with conventional colloid mills.