Admix Industrial Mixers for Chemical Applications

Admix: Solve Your Toughest Chemical Mixing Challenges, Maximize Efficiency, and Ensure Safety.

Are you facing challenges with inconsistent mixing, long batch times, or safety concerns in your chemical manufacturing plant? Admix provides robust, high-performance industrial mixing solutions designed to overcome these hurdles and deliver superior results.

Key Features

Reduced Processing Time

High-efficiency dispersers dramatically reduce batch times, increasing throughput.

Exceptional Dispersion

Eliminate agglomerates, fisheyes, and inconsistencies, achieving homogenous blends every time.

Enhanced Safety

Explosion-proof options (Class 1 Div. 1 and Class 1 Div. 2) ensure safe operation in hazardous environments.

Highly efficient dispersers

Reduce batch times, reduce maintenance costs, reduce clogged media mill screens, eliminate air entrainment and quickly eliminate agglomerates.

Wide Range of Applications

Adhesives & sealants, agro & specialty chemicals, battery production, biofuel & petrochemicals, composites, ceramics & glass, inks & pigments, paints & coatings, plastics, polymers, resins, & elastomers.

Industry Expertise

Trusted by leading chemical manufacturers for proven performance.

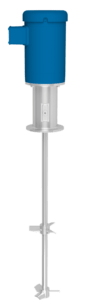

High Shear and Low Shear Chemical Mixers

Admix’s Hygienic Batch Mixing solutions offer a comprehensive range, from high-shear Rotosolver and Rotostat dispersers for demanding emulsions and dispersions to low-shear Rotomixx and Rotomaxx II agitators for gentle blending and large-volume holding. This includes the Benchmix series for laboratory and pilot plant applications, allowing for seamless scale-up to full production while maintaining the highest sanitary standards.

Inline Mixing & Milling for Chemical Processing

Admix’s Inline Mixing & Milling solutions, including the Dynashear, Boston Shearmill, and Admixer, deliver efficient and hygienic processing for demanding industries. These units offer a range of capabilities, from high-shear milling and homogenization to gentle, low-shear blending, all while meeting strict 3-A, USDA, and FDA sanitary standards.

Powder Induction Systems for Chemical Applications

Admix’s Powder Induction Systems, including the Fastfeed, PIC, and Optifeed models, offer rapid and efficient incorporation of powders into liquids, specifically designed for hygienic and sanitary applications. These systems provide controlled feed rates up to 450 lbs per minute, handle high solids concentrations, and minimize dust and air entrainment, all from an ergonomic, easy-to-use, and cleanable design.