Admix Admixer™ CX - Static Mixer and Blender

Admix Admixer CX: Static Mixing and Blending for Chemical Processes

The Admix Admixer CX is a static mixer and blender designed for efficient and predictable mixing of miscible fluids in chemical processing applications. With no moving parts, the Admixer CX offers a low-maintenance, low-energy, and highly reliable solution for blending, dispersing, reacting, or heating chemicals within a pipeline.

Ideal for

Blending, dispersing, reacting, and heating chemicals in continuous processes, including applications with high viscosity ratios, volumetric ratios, or density ratios.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

Benefits of Admix Admixer CX

How the Admix Admixer CX Works

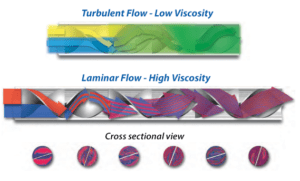

The Admixer CX utilizes a series of precisely engineered, stationary mixing elements within a pipe. These elements, typically elliptical or helical in shape, divide and reorient the fluid flow. In laminar flow, the elements repeatedly split and recombine the fluid streams, ensuring complete mixing regardless of viscosity, density, or velocity differences. In turbulent flow, the Admixer CX induces radial momentum and inertia reversal, eliminating stratification and temperature gradients. The smooth transitions and triangular risers connecting the elements minimize energy loss and prevent eddy dissipation. This design ensures uniform shear and approaches ideal plug flow, making it suitable for both blending miscible fluids and creating fine dispersions of immiscible fluids or gases.

While many geometric shapes are used to create homogeneous flow, the degree of energy and mixing efficiency is not addressed. Thus, by using an elliptical or helical shape, smooth transitions are possible and no energy is wasted in back mixing. Triangular risers are in use to connect the angled elliptical shapes to prevent eddy dissipation at the element edges.

When in laminar flow, two or more fluids will remain adjacent to each other indefinitely unless disrupted. Therefore, the mixing elements divide the fluids and reorient by 180 degrees, by reversing from left hand to right-hand orientation, the rapid reversal at the interface enhances the mixing effect.

Admixer CX: Distinguished by its performance, reliability and versatility

-

- No Moving Parts: Eliminates mechanical wear and reduces maintenance.

- Predictable Mixing: Achieves complete homogeneity through geometrically precise flow division.

- Low Energy Consumption: Requires significantly less power than dynamic mixers (50-90% less).

- Low Capital and Maintenance Costs: Simple design and robust construction.

- Versatile: Handles a wide range of viscosities (over 1 million cps) and flow rates.

- Corrosion/Abrasion Resistant: Available in various materials, including Teflon and exotic alloys.

- Customizable: Sanitary Clamps, Threaded Ends, Flanged Ends, Tri-Clamp connections, and special surface finishes available.

Related Process Equipment

The Admix Admixer CX works seamlessly with other process solutions, including:

- Boston Shearmill CX– for high-shear dispersion

- DynaShear CX – inline high-shear mixing and emulsification

- Rotosolver CX & Rotostat CX – powerful high-shear mixing solutions

- Pentair Sudmo valves: Pentair Sudmo butterfly valve, Pentair Sudmo mixproof valve for fluid control

- Stainless steel pump cart – ideal for mobile processing

- TC 130 for temperature-sensitive processes

- Piab vacuum conveyor, Piab filters, and Piab parts for optimized powder handling