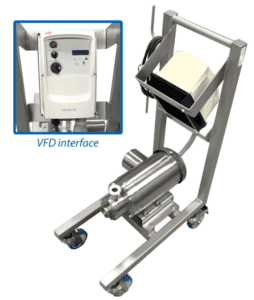

Admix DynaShear® CX - Chemical Inline Mixer

Admix DynaShear CX: Inline High-Shear Mixing for Demanding Chemical Processes

The Admix DynaShear CX is a high-performance inline high-shear mixer designed for continuous processing in demanding chemical applications. Its unique dual-stage design, combining both axial and radial mixing elements, delivers exceptional shear and flow characteristics, resulting in superior particle size reduction, emulsification, and dispersion – often in a single pass.

Ideal For

Emulsifying, dispersing, deagglomerating, and homogenizing a wide array of chemicals, including polymers, resins, adhesives, coatings, pigments, and more.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

Dynashear® CX Benefits: The Advantages of Advanced Inline Mixing

How the Dynashear CX Works:

The DynaShear CX features a tandem head design with two distinct mixing stages. The primary axial stage consists of a high-flow rotor feeding into a stator with multiple small ports. This forces material between the rotor and stator faces, creating intense mechanical and hydraulic shear. The secondary radial stage features a radial, high-flow rotor discharging through a slotted stator. This provides additional mechanical and hydraulic shear, and the centrifugal force pushes the mixture outwards, resulting in a substantial momentum change and further refinement. This two-stage process ensures thorough mixing and particle size reduction, often achieving results in a single pass that would require multiple passes with conventional mixers.

DynaShear Models and Specs:

- DS-215 (lab scale): 2 HP, up to 22 gpm, 1.5″ inlet, 1″ outlet.

- DS-425: 5 HP, up to 65 gpm, 2.5″ inlet, 2″ outlet.

- DS-575: 20 HP, up to 175 gpm, 4″ inlet, 3″ outlet.

- DS-850: 40 HP, up to 350 gpm, 6″ inlet, 4″ outlet.

- All models feature high tip speeds and pressure ratings up to 450 PSI.

Available Options

- Stator options: Coarse (21 slots), Standard (36 slots), Fine (68 slots)

- Casters

- Special Ports

- Lab scale model includes VFD and is mounted to cart

- Balanced single or double mechanical seals

Dynashear Quickship Program

Minimize lead times with our Dynashear® QuickShip Program! Select configurations of the DS-215, DS-425, and DS-575 models are available for immediate dispatch:

* **SHIPS WITHIN 2 DAYS OF ORDER!**

* **EASY TO INSTALL!**