Admix Rotosolver® CX - High Shear Mixer

Rotosolver CX: Unmatched High-Shear Mixing for Chemical Processing

The Rotosolver CX is the industry-leading in-tank high-shear mixer, delivering superior dispersion and faster batch times than conventional mixers. Its unique, single-shaft design with a one-piece, clean-in-place (CIP) mix head provides high-intensity shear and exceptional flow, ensuring complete dissolving, hydrating, or suspension of your chemical ingredients.

Key Features

Faster Batch Times

Up to 6 times faster than competitors, with 30-50% less energy consumption.

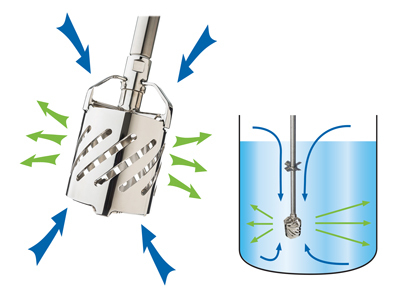

Superior Mixing Action

Four-stage mixing process for optimal dispersion and particle size reduction.

High Flow Rates

200-600% higher flow rates than comparable mixers.

Versatile

Handles viscosities from 1-50,000 cPs. Scalable from lab models to production sizes up to 100 HP.

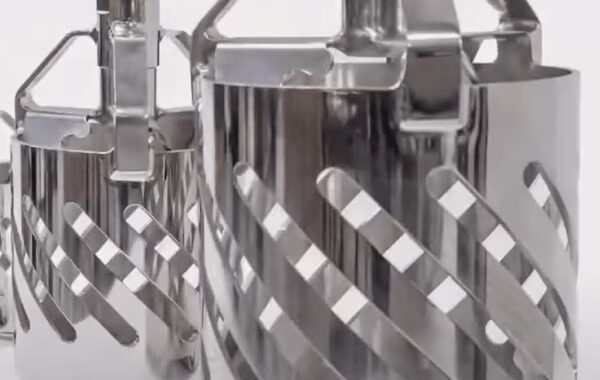

Hygienic Design

One-piece CIP mix head and obstruction-free design for easy cleaning.

Customizable

Various head sizes, motors, seals, and mounting options available

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

BENEFITS

Try the Rotosolver CX High Shear Mixer Before You Buy

Want to see the Rotosolver in action or take high shearing mixer for a test drive? Our comprehensive mixing equipment services can improve your process and bottom line today.

- Get a customized quote

- Schedule free formula testing in our lab

- Request free passes to trade shows we’re attending

- Learn about our trial program incentives or request an onsite demo

- Get guaranteed scale-up with a process assurance warranty to ensure your product is to made to spec and goes to market faster

If you are a meat and poultry processor, then check out our Rotosolver RXRS which is designed specifically for your industry and combines the high shear technology of the Rotosolver with a low maintenance bearing frame. Plus, the sealed drive assembly eliminates water intrusion and stands up to the toughest wash-down environments.

HIGH SHEAR TECHNIQUE

The Rotosolver CX Advantage:

- Complete Dispersion: Eliminates fisheyes and agglomerates, ensuring 100% ingredient utilization.

- Faster Processing: Reduce batch times by up to 6x.

- Lower Energy Costs: Up to 50% more energy-efficient than competing mixers.

- Easy to Clean: Single-shaft, one-piece mix head designed for CIP.

- Versatile and Scalable: Suitable for a wide range of viscosities (1-50,000 cPs) and batch sizes.

- Customizable: Multiple options available