Admix DynaShear® Sanitary Inline Mixer

Admix Dynashear® Sanitary Inline Mixer: Revolutionizing Continuous Processing for Demanding Industries

For professionals seeking advanced solutions in continuous processing, the Admix Dynashear® Sanitary Inline Mixer stands as an industry benchmark. Renowned for its high speed and high shear mixer capabilities, the Dynashear excels as an emulsifier in diverse applications, from dairy and beverage to pharmaceutical and chemical processing. With hundreds of successful installations globally, this inline mixer is engineered for efficiency and reliability.

Built entirely from robust 316 stainless steel, including internals, housing, and shafting, the Dynashear ensures sanitary operation and long-lasting performance. Its unique dual-stage axial and radial heads are meticulously designed to optimize throughput and flow, delivering unparalleled admixing and mixing performance. Achieve precise droplet and particle size reduction down to the 3-5 micron range with exceptional distribution, enhancing product quality and consistency. For operations requiring even finer particle reduction, consider exploring the capabilities of the Admix Boston Shearmill for sub-micron results.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

Dynashear® Benefits: The Advantages of Advanced Inline Mixing

How the Dynashear® Achieves Superior Inline Mixing

The Dynashear’s exceptional performance in admixing vs mixing scenarios stems from its innovative dual-stage tandem head design. This system optimizes droplet size reduction, particle size distribution, and flow rates, even under varying viscosity conditions, surpassing competitive high shear inline mixer performance. A single pass through the Dynashear often yields product quality comparable to multiple passes through conventional mixers.

Dual-Stage Tandem Head Design

Primary Axial Stage

This stage features a high-flow rotor feeding into a stator with multiple small ports. This configuration forces material between stator faces and out through the ports. The result is significant mechanical and hydraulic shearing action, effectively “pre-mixing” the material before it reaches the secondary stage.

Secondary Radial Stage

The radial stage employs a high-flow rotor that discharges through a slotted stator. This stage provides further mechanical and hydraulic shear through centrifugal force, pushing the mixture along the stator’s radius for high-speed expulsion. This momentum change enhances residence time, further refining the mixture to the desired consistency.

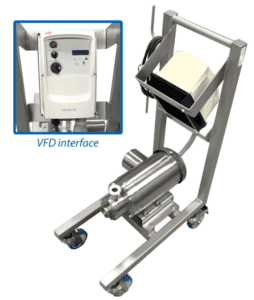

Lab Scale Dynashear

The Dynashear 215 is a benchtop lab mixer designed for product development, simulation, and scale-up processes. Mounted on a mobile cart and equipped with a Variable Frequency Drive (VFD), the Lab Scale Dynashear® ensures accurate and repeatable results, bridging the gap from laboratory experimentation to full-scale production.

Dynashear Quickship Program

Minimize lead times with our Dynashear® QuickShip Program! Select configurations of the DS-215, DS-425, and DS-575 models are available for immediate dispatch:

* **SHIPS WITHIN 2 DAYS OF ORDER!**

* **EASY TO INSTALL!**