Admix Rotosolver® - High Shear Mixer

Admix Rotosolver Mixer: Maximum Mixing Efficiency Meets Clean-in-Place Convenience

If your production line requires sanitary, high shear mixing equipment with intense mixing vortex control, superior wetting out of powders, and an easy-to-clean, 3-A compliant design, the patented Rotosolver high shear mixer is the solution. The Admix Rotosolver is the industry’s leading in-tank high shear mixer, designed for manufacturers who demand superior powder dispersion, efficient mixing, and sanitary operation. It delivers unmatched performance in wet-out capabilities while maintaining compliance with stringent sanitary standards.

Purpose-built with advanced CFD-optimized design, the Rotosolver provides high-intensity mechanical and hydrodynamic shear through its innovative single-shaft architecture. Its one-piece mixing head enables both superior performance and clean-in-place convenience, setting new standards for industrial mixing technology.

The Rotosolver simplifies complex mixing operations with its obstruction-free design and clean-in-place capabilities, allowing operators to achieve consistent results while minimizing maintenance time. Its user-centric design ensures easy integration into existing processes and straightforward operation.

By combining faster powder dispersion, reduced energy consumption, and simplified cleaning procedures, the Rotosolver delivers immediate operational cost savings while increasing production efficiency. Its sanitary compliance and robust construction ensure long-term reliability and regulatory conformity.

Why Choose R-CAP Process Equipment?

At R-CAP Process Equipment, we provide top-tier industrial process solutions designed to optimize your liquid and dry processing operations. From Admix high shear mixers to Piab vacuum conveyors and integrated process systems, our range of products ensures maximum efficiency, reliability, and precision.

BENEFITS

TRY THE ROTOSOLVER HIGH SHEAR MIXER BEFORE YOU BUY

Want to see the Rotosolver in action or take high shearing mixer for a test drive? Our comprehensive mixing equipment services can improve your process and bottom line today.

- Get a customized quote

- Schedule free formula testing in our lab

- Request free passes to trade shows we’re attending

- Learn about our trial program incentives or request an onsite demo

- Get guaranteed scale-up with a process assurance warranty to ensure your product is to made to spec and goes to market faster

If you are a meat and poultry processor, then check out our Rotosolver RXRS which is designed specifically for your industry and combines the high shear technology of the Rotosolver with a low maintenance bearing frame. Plus, the sealed drive assembly eliminates water intrusion and stands up to the toughest wash-down environments.

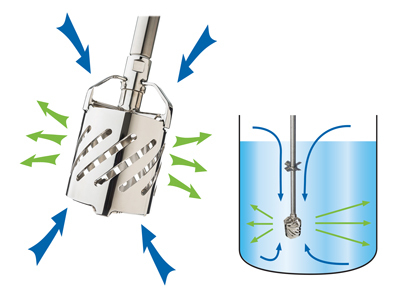

HIGH SHEAR TECHNIQUE

The Rotosolver combines the shearing capabilities of a high-speed toothed rotor and a slotted stator with the additional advantage of high flow/circulation from the dual rotor blades. This unique mixing head design of the disperser provides a four-stage mixing action:

- Product flow is drawn into the mixing head from above and below. As flow is drawn in, materials and powders pulled down from the top (typically the toughest to disperse) are immediately exposed to two additional mechanical shear zones and one shear zone from the bottom. Therefore, these materials are then immediately mechanically ripped by the teeth on the rotor’s discharge at the top and bottom of the stator.

- The counter-current streams converge within the stator causing high turbulence and hydraulic shear. As a result, no momentum loss from obstructions within the stator.

- Centrifugal pressure forces material to the stator, where it is subjected to further shear from the edges of the expanded slots.

- The high-velocity radial discharge combines with slower-moving tank flow for additional hydraulic shear and circulation. Contact us for more info!