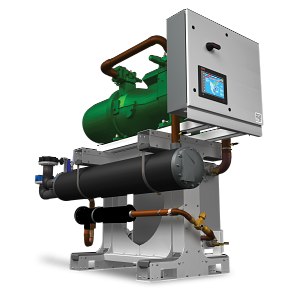

STERLING TRIDENT GS SERIES CENTRAL CHILLERS

Sterling Trident™ GS Series Central Chillers

The TridentTM GS Series Modular Central Chiller integrates advanced technologies with proven component design to offer a capable and innovative process chilling solution.

The state-of-the-art controls provide the operator with intuitive command structures while offering critical unit performance data in understandable dashboard sets. Individual circuit capabilities range from 50 tons to 120 tons of cooling capacity. Each circuit has the ability to parallel with other TridentTM circuits of the same size for maximum system scalability. Drone circuits offer market leading connectivity, as every unit has the same control set. This allows TridentTM to offer the ultimate plug-and-play capability currently available and can even integrate with Sterling pump tanks.

FEATURES

MECHANICAL FEATURES

- Semi-hermetic dual screw with crank case heaters and pressure sensors

- Stainless steel, copper brazed plate evaporator

- TS Tech™ tool-less evaporator inlet strainer and evaporator back flush ports and strainer blow down valve

- Remote air-cooled condensers are rated to -20°F (-29°C) ambient and feature aluminum v-coils with washable filters, VFD fan control, and ambient temperature sensors

ELECTRICAL FEATURES

- Non-ferrous construction on chilled water side

- Fully accessible NEMA 12-style electrical control enclosure with non-fused power disconnect

- Single-point power and ground wiring connection per module

OPTIONAL FEATURES

- Shell and tube evaporator designs for heat transfer fluid with higher particulate

- Evaporator manifold assemblies for water-cooled or air-cooled units

- Condenser manifold assemblies for water-cooled units

- Audible/visual warning and fault indicators

- Variety of communication protocols to include Ethernet, Modbus, and BACnet

- Chilled water line flow sensor

- Condenser out temperature sensor for water-cooled units

- To or from process temperature sensor, provided loose for customer install

- Chill in / chill out pressure sensor on the input and output of the evaporator

- Evaporator pressure differential sensors for determining pressure drop within the evaporator