Vacuum Conveyors

What Are Vacuum Conveyor Systems?

Effective production starts with the right tools. Whether you work in food processing or pharmaceutical processing, you need high-quality equipment that will get the job done efficiently and last for years down the road. If you’re in the market for a vacuum transfer system for powders and other materials, we’re here to help you pick the right one. Keep reading to learn how vacuum conveyors work and how they can benefit you. Or contact a R-CAP engineer today for a consultation.

A vacuum conveyor is a type of material conveying system that uses vacuum suction to transfer powders and other dry materials from point A to point B through a series of tubes. The vacuum feature protects materials from leaking and getting damaged during the transfer process. It also enhances production efficiency, increases production capacity, and ensures worker safety. Vacuum conveyors are commonly used in the food processing, pharmaceutical, and chemical industries—among others.

How Do They Work?

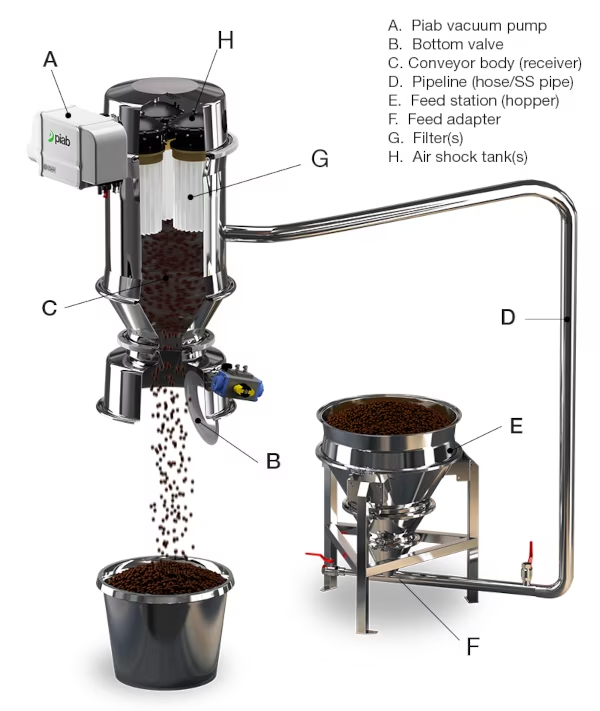

Vacuum conveyors use air and suction power to move dry materials—like powders and granules—from one suction point to a discharge location through a pipe system. The vacuum is typically powered by a compressed air-driven vacuum pump.

Functions

The major functions of a vacuum conveying system include a pickup point—like a hopper, bag dump station, bulk bag unloading system, or a feed wand for the drum. The conveyor body is the other major function, which is where a vacuum or mechanical pump is attached to provide suction. This is when the powder or other bulk product is pulled from the pickup point, transferred into the conveyor body, and ultimately discharged through the bottom valve.

Top 4 Benefits of Vacuum Conveyors

If you’re on the fence about whether a vacuum conveyor is worth the investment, consider the top four benefits this equipment offers users.

- No Mechanical Conveyors: Thanks to their convenient suction power, vacuum conveyors eliminate the need for manual handling or mechanical conveyors to transfer powdered products.

- Dust-Free: By protecting powders and other dry materials from leaking during transfer, vacuum conveyors ensure a dust-free working environment.

- Minimum Floor Space: Due to their relatively compact size, vacuum conveyors require minimal floor space in a facility.

- Reduces Product Waste: It is also a gentle way of transporting the product, meaning that the product will stay intact, resulting in minimum product scrap.

How Are Vacuum Conveyors Used in the Food Industry?

Food-grade vacuum conveyors ensure the safe and efficient transfer of flour, fine powders, and other materials used in the food industry. They’re also extremely reliable, user-friendly, and easy to clean. A growing number of food processing companies are choosing vacuum conveyors over traditional mechanical conveyors because they can be configured to meet specific production requirements.

Here’s a list of five common vacuum conveyor applications in the food industry.

- Emptying & Loading

- Filling Bags

- Mixer Loading

- Dosing & Measuring

- Recycling

10 Factors to Consider When Choosing a Vacuum Conveyor

Knowing which vacuum conveyor to choose can be overwhelming. We recommend considering the following features before making a purchase.

- Material Bulk Density

- Conveying Distance

- Conveying Rate

- Batch vs. Continuous Conveying

- Material Characteristics

- Material Container Receipt

- Pick Up Point

- Process Equipment

- Headroom

- Plant Site and Industry Environment

The Trusted Name in Vacuum Conveyor Solutions

As the market’s leading vacuum conveyor supplier, R-CAP Process Equipment has an innovative solution for all your dry processing needs. We offer a wide selection of premium vacuum conveyors that will help you meet your goals and receive a return on your investment. Browse our collection today to find the right vacuum conveyor for your business or contact us today for a consultation.